Maylands Brickworks

The clay deposits along the Swan River have provided high quality brick-making material since the earliest days of European settlement.

Several brick-making companies operated kilns. The Maylands brickworks was the most advanced brickmaking plant when it opened in 1927. Across the river from Maylands, the Brisbane Wunderlich brickworks operated at Ascot.

Before establishing Maylands, Brickworks Robert Oswald Law and William Atkins purchased the Helena Vale Brickworks in Midland Junction on the Helena River.

Soon after they bought shares in the Cardup Brick Company in Perth’s southeast.

Law established a Hoffman kiln at Helena Vale in 1910 and in 1913 took over Armadale Brickworks from operators Coombe to make him WA’s biggest producer of clay bricks.

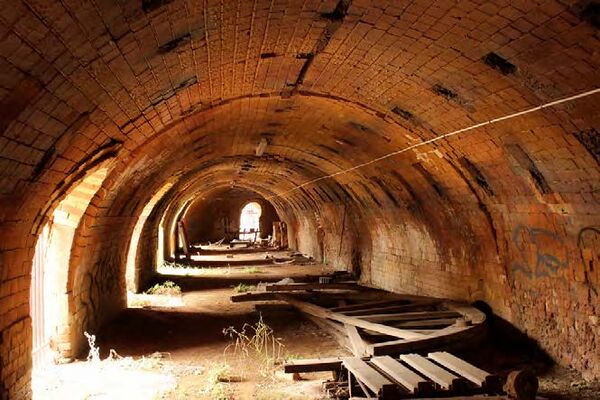

In 1927 Maylands Brickworks was opened. It was described as the most highly technical plant in Australia. During maximum production with two Hoffman kilns, two pug mills and extensive drying sheds, the Brickworks produced 14 million bricks per year to serve a period of rapid infrastructure expansion in WA.

It is now the only remaining Hoffman kiln in Western Australia, and one of the only five remaining kilns in Australia. The place is an important example of brick making technology and is a significant example of industrial archaeology.

The kiln and chimney comprise prominent landmarks on the Maylands peninsula.

Nearby lakes were formerly the clay pits from which the brick-making material was excavated.

Location

How does a Hoffman kiln work?

The starting point for brick-making is soft clay, usually extracted from pits near rivers. The clay is mixed with other minerals to provide appropriate colour and consistency, and is moulded into bricks, or extruded from a machine and cut into bricks. The bricks are moist and soft at this stage. They are allowed to dry for weeks to become “green bricks”. When the Maylands brickworks were in operation, there were many drying sheds. Today there is only one left, in relatively poor condition.

Once firm enough, the green bricks are stacked in a way that allows air to pass through the stacks. Before the Hofmann kiln was invented, the stacks of bricks were placed around a tall chimney. Fuel such as coal or wood was stacked around the outer stacks of bricks and the brick stacks were covered with a temporary roof of tiles and dirt. The fuel burned for a couple of days, heating the bricks to about 600 – 700 °C, baking the clay into hard bricks. Even higher temperatures result in vitrification: the clay particles start to melt and become ceramic, resulting in a harder and more durable brick. With burning completed, the stacks cool down and the bricks can be removed after a few days.

The Hofmann kiln was a major improvement when it was first invented in Germany in the 1850s [1]. It consists of an oval arrangement of chambers around a tall chimney shown in the diagram below. A large space above the kiln chambers allows for fuel (coal, or natural gas) to be fed to the firing zone below. A roof over the top enables the kiln to be used regardless of weather conditions.

Unlike the original batch fired kilns, it provides a continuous brick-making process: there is no interruption to allow fired bricks to cool and fresh green bricks to be stacked.

Green bricks were stacked on steel trolleys which were wheeled through openings into the kiln tunnel running around the lower level of the kiln. Look at the diagram below.

Cool air first passes through stacks of bricks in the tunnel that are gradually cooling after being fired. This pre-heats the air before it reaches the firing zone where fuel is burning. The hot air from the bricks being fired passes along the tunnel through the stacks of waiting green bricks, drying and pre-heating them gradually. Then the hot air is channeled by vents to the chimney where it rises, generating a low pressure zone that continues to draw air through the chambers of the kiln.

The diagram shows how green bricks (rawmix) are loaded into a new chamber each day on trolleys, replacing recently fired bricks (clinker), so that the firing zone moves one chamber forward each day. This way, the fires burn continuously, using pulverized coal fed from the space above the kiln through holes in the top of the kiln which serves as the floor for the space above. The kiln requires less fuel than the original batch-fired kilns because the recently fired hot bricks pre-heat air arriving at the burning zone, and the hot air from the firing chambers helps to dry the green bricks.

William Bull, a British engineer, adapted this design for India in the 1870s. While the layout was the same, a temporary roof and moveable chimneys adjacent to the firing zone greatly reduced the capital cost. There were no mechanized trolleys: the bricks were stacked by hand. In the 1990s, moveable chimneys were banned because of safety risks, being replaced by a fixed central chimney as used in the Hofmann Kiln.

A more recent variation is the zig-zag kiln in which the air follows a zig-zag path [2], resulting in less pollution and more even brick quality. Some even more energy efficient and less polluting kilns are in use, adapted from designs developed in China and Vietnam.

The Maylands brickworks was partly mechanized: the bricks were stacked on steel trolleys that were rolled into the kiln chambers.

Most kilns in industrialized countries now use fully automated variations on the tunnel kiln which uses the same principles as the Hofmann and Bull kilns. Fired clinker bricks still pre-heat air arriving at the firing zone, and the exhaust gases from the firing zone help to dry the green bricks. However, instead of loading and unloading separate chambers, and progressively moving the firing zone as in the Hofmann design, the bricks move through a tunnel on trolleys instead. The firing zone remains in a fixed position that enables more automation and more precise temperature control.

In recent years there have been significant efforts to improve the efficiency and reduce pollution from brick kilns in developing countries. The use of bio-fuels such as waste from rice and wheat production is important to reduce CO2 emissions [3][4]

Maylands Brickworks Timeline

1881: Robert Oswald Law, a contractor migrant from Victoria, partners with William Atkins, a prominent brick, tile and pipe manufacturer, as building contractors.

1922: Law founds Metropolitan Brick Company Ltd. Also finds extensive clay deposits on the Maylands peninsula and purchased land there.

1927: Law and MBC Ltd establishes complete brickworks at Maylands with Hoffman kiln.

1934-6: One of Helena Vales Hoffman kilns was dismantled and re-erected at Maylands to the north of the 1927 kiln.

1946: Maylands Brickworks described as the most highly technical plant in Australia. 130 employees.

1967: Hoffman kilns powering changed to oil fired system from coal.

1968: Chimney stack to one kiln sustains damage in Meckering earthquake. Repairs undertaken.

1973: Metropolitan Brick Company Ltd acquired by H.L. Brisbane & Wunderlich Ltd.

1976: H.L. Brisbane & Wunderlich Ltd expand operations at their Cardup site with full automation.

1978: H.L. Brisbane & Wunderlich Ltd become known as Bristile Ltd. 51 Employees at Maylands. Second Hoffman kiln closed by now.

1980: Bristile Ltd sell land and clay pits to City of Stirling but continue use of site and clay resource.

1982: Bristile merge with Monier Ltd to become Metro Brick. Maylands site deemed too labour intensive, determination made to cease production. Helena Vale kiln to the north demolished.

1983: 1927 Hoffman kiln cooled down. Bristile vacates site. City of Stirling negotiate with Bristile regarding items to be retained on site. Major concern about impact of cooling effect on Hoffman kiln structure.

1985-7: City of Stirling abandon plans to use clay pits for rubbish disposal. Area re-zoned for residential instead. Funding gained to tackle some urgent works to kiln and fencing of site.

1990: First Conservation Plan commissioned – advises retention of building standing today for site interpretation needs.

1992: CoS allocate $0.5m to essential repairs and site safety through to1994.

1998: Ownership transferred to City of Bayswater with shift of Maylands area in local government boundary changes.

2010: CoB commission structural engineer’s report – advises only ongoing maintenance needed if no public access allowed.

2013: Palassis Architects complete a comprehensive conservation plan [5]

2024: The Western Australian State Government and the City of Bayswater have not yet agreed on the long-term future of the site. However, the kiln building has been maintained and several options for future use of the site are being considered [6].

James Trevelyan, Garon Deutsch June 2025

References

- ↑ Wikipedia – Hofmann Kiln

- ↑ Saithel, S., Lalchandani, D. and others (2012), Monitoring brick kilns and strategies for cleaner brick production in India, Retrieved June 2025, Shakti Sustainable Energy Foundation, 164 pp.

- ↑ ICIMOD: Zig-zag brick kiln operation (2023), retrieved June 2025

- ↑ CAEM: Factsheet about brick and tiles kiln technologies in Latin America (2015), retrieved June 2025

- ↑ City of Bayswater (2013) Maylands Brickworks Conservation Management Plan, Retrieved June 2025.

- ↑ City of Bayswater (2024), Conservation Plan for Maylands Brickworks, Retrieved June 2025